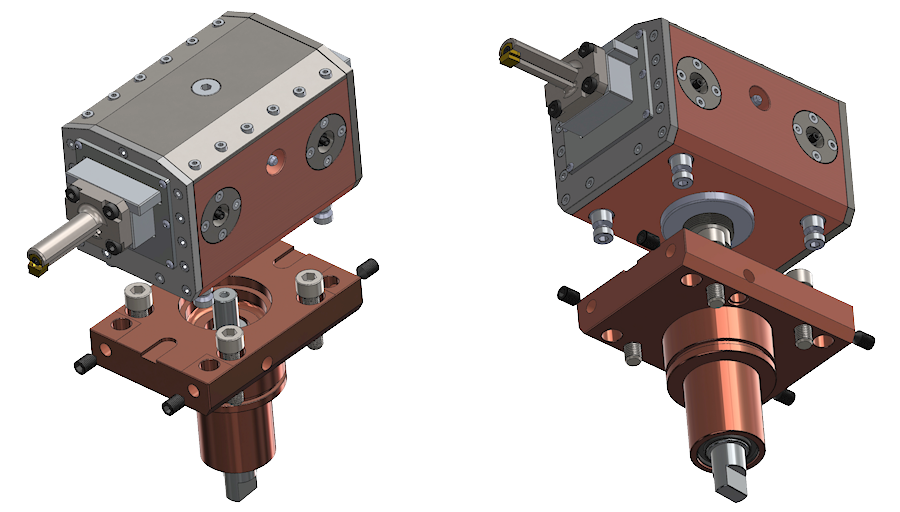

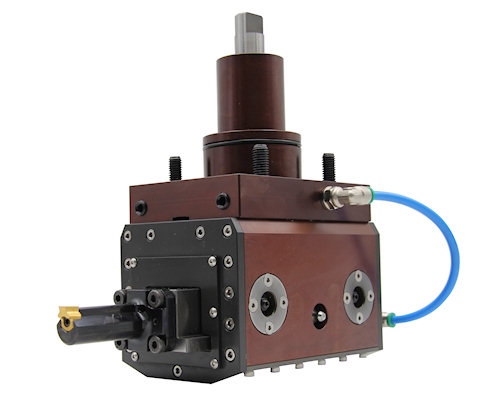

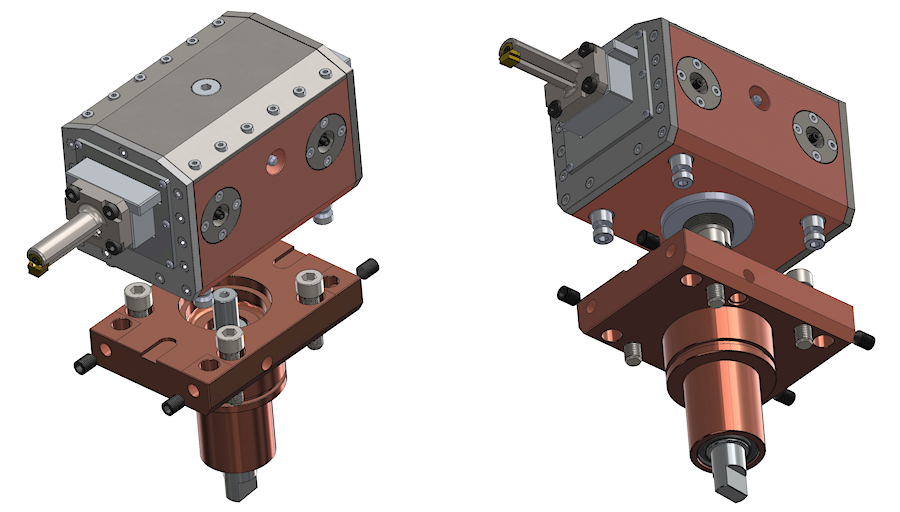

The REV motorised slotter is designed to solve, in the most efficient way, the problem of having to perform certain processing operations on a CNC lathe, from a simple keyway to internal or external toothed profiles.

The REV motorised slotter is designed to obtain maximum rigidity. This feature allows the insert to be used for a very long time and the processed surface to have an excellent degree of finish.

There are remarkable advantages in using this slotter: in addition to its extremely fast processing speed, the piece does not need to be moved on other machines, thus avoiding further tool set-ups.

The REV motorised slotter has several adjustments, which are useful for achieving correct processing, and can perform internal or external processing.

The REV motorised slotter is protected by patent.

Longitudinal error correction

The working angle of the motorised slotter can be changed. This operation is used to correct any longitudinal errors. To do this, all you need is a 5mm Allen key. Turn the Allen key clockwise or anticlockwise to change the cutting angle of the motorised slotter.

This type of adjustment is protected by patent.

Symmetry correction

To correct any symmetry errors, if using a lathe without a Y-axis, simply unscrew the four bolts fastening the front of the tool to the moving central component. Then, by turning the Y-axis adjustment pin on the back of the aforementioned component with a 6 mm hex key, the tool will have an offset of +/- 0.5 mm, which is enough to correct any symmetry errors, and will create the missing axis.

This type of adjustment, which is indispensable for processing exactly in the centre of the piece to be worked, is protected by patent.

External profile processing

This short video shows an external processing: making a DIN 5482 module 2.5 Z=30 external grooved profile.

The processed material is alloy steel with 35 HRC hardness.

The processing time of a single housing is 4 seconds, while the total time for processing an entire toothed profile is about two minutes.

Given the extreme rigidity of the tool, processing is very simple and with an excellent degree of finish.

In order to correctly and efficiently use this tool, REV srl provides its customers free of charge with a specially designed programme. This programme is available for all CNC lathes on the market.

Internal processing

This short video shows an internal processing: making eight keyways for an 8 mm thick key.

The processed material is alloy steel with 35 HRC hardness.

The processing time of the single key is 6 seconds, while the total time for processing the 8 keyways is about 50 seconds.

Given the extreme rigidity of the tool, processing is very simple and with an excellent degree of finish.

In order to correctly and efficiently use this tool, REV srl provides its customers free of charge with a specially designed programme. This programme is available for all CNC lathes on the market.

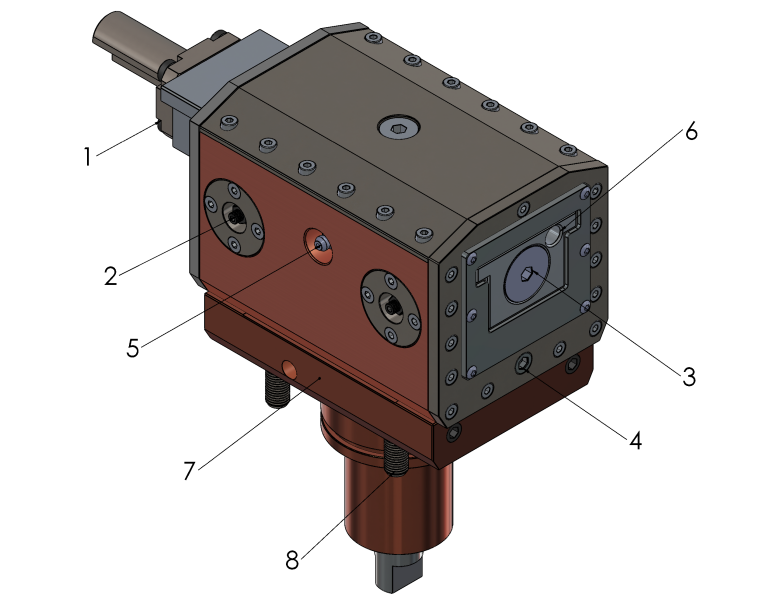

1) Tool clamping screws

The tool clamping screws must be slightly unscrewed before correcting any symmetry errors. Before resuming the work, make sure you have tightened the tool clamping screws again.

2) Adjustable gib screws

After using the slotter for a long time, it will be necessary to eliminate the potential play created in the tool. Do this by unscrewing the hexagonal nut, tightening the centre screw and then screwing the hexagonal nut back on. Repeat this operation on all four gibs of the slotter.

3) Y-axis adjustment pin

This is used to correct any symmetry errors between the hole and the piece currently being processed. After unscrewing the tool clamping screws 1, turn the Y-axis adjustment pin either clockwise or anticlockwise. This will allow you to move the tool along the Y-axis. The adjustment range is +/- 0.5, which is extensive enough to correct all of the symmetry errors on lathes without a Y-axis.

4) Cutting angle adjustment screw

This screw is used to correct any conical errors due to mechanical bending. By turning it clockwise or anticlockwise the cutting angle can be changed by about +/- 3°. This range is sufficient enough to correct any conical errors.

5) Grease nipples

These two grease nipples are built into the external structure of the motorised slotter and are used to grease after about 10 hours of use, meaning the effective operating time of the tool (see example of calculation for greasing).

6) Threaded hole for internal 3/8” gas supply

All of the tools feature holes for the supply of coolant. The internal supply is recommended more than the external supply and allows the lubricant to be directed to the cutting area.

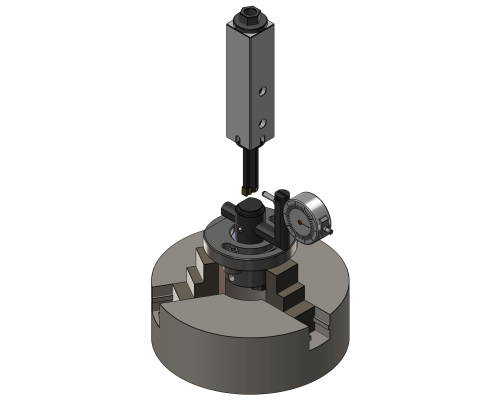

7) Alignment area

This is the area to be used for the comparator control.

8) Bolts clamping the slotter to the tool turret on the lathe

These are bolts that fasten the slotter to the tool turret on the lathe.

FIRST USE

Mount the slotter onto the lathe. Slightly loosen the 8 clamping bolts and align the slotter using a comparator. The latter is to be placed on alignment area 7. When the slotter is perfectly aligned, tighten the 8 clamping bolts and operate the slotter at 150 movements per minute for about 10 minutes. Grease the moving slide with common oil for guides. This will soften the gaskets and break in the slotter before use.

GREASING

To preserve the mechanics, we recommend greasing the slotter every 10 hours of use, meaning actual use (see example of calculation for greasing).

Preferably use Persian Poligrease EP 1.

Proceed as follows in order to introduce the right amount of grease:

- Loosen the cap on the motorised cover;

- Start introducing the greasing using the special grease nipples;

- Stop the introduction of grease when it comes out from the hole;

- Tighten the cap back on and start using the tool again.

Example of calculation for greasing

If 2 minutes are required to produce one piece and 10 seconds are needed to

make just the keyway for a feather key, grease after about 3600 pieces.

MAINTENANCE

After a long period of use (about 1,000 hours), maintenance will need to be performed on the slotter, replacing the parts subject to wear such as bearings, gaskets, etc.

INTERNAL/EXTERNAL PROCESSING

This motorised slotter can perform internal or external processing.

Simply reverse the motorised rotation direction as follows:

control M03 = internal processing

control M04 = external processing.

Depending on whether internal or external processing is to be done, the tool must be fixed with the insert following the cutting direction.

DETACHMENT DURING THE RETURN PHASE

During the return phase, the tool detaches from the processed surface by 0.25 mm. This movement is essential to preserve the integrity of the insert.