Our Story |

Our Work |

Our company, F.P. Officina Meccanica, was founded in 1998 based on Mr. Paolo Franchini's 18 years of experience in the mechanics industry. For many years, the company carried out slotting and broaching activities for third-parties, working in the hydraulic, automotive, biomedical, speed reducer, gear construction and earth moving machinery industries etc.

Over time, in addition to slotting and broaching, the company began CNC lathing and milling mechanical parts, which also often involved producing internal keyways, and six-spline PTOs. Not only did it require a large amount of time to set up the various tools, it was also very complicated to perform these processes on traditional broaching and slotting machines due to frequent problems in relation to clamping the workpieces and difficulties in obtaining the required level of precision. The idea of producing, in-house, a tool to perform broaching directly on CNC lathes or machining centres developed from the need to solve these issues and difficulties, and was made possible by extensive experience with CAD CAM design.

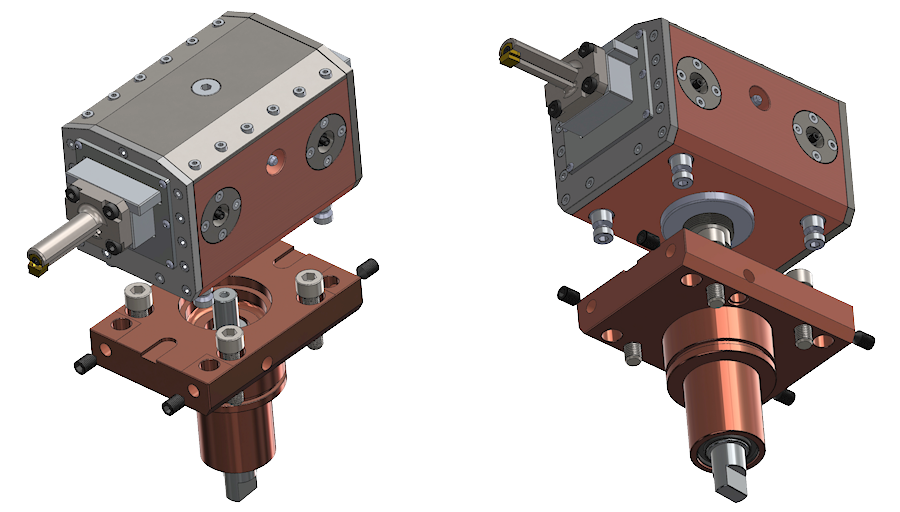

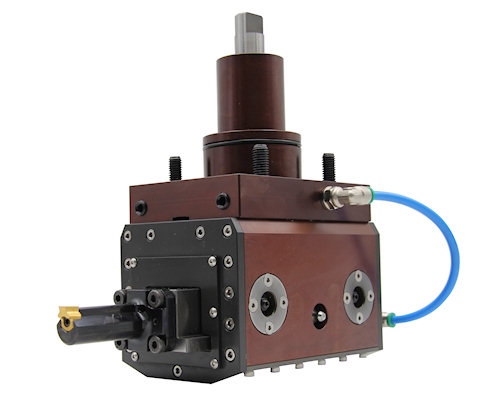

This is how the "REV Broaching Tool" system for CNC machines was developed, which, after years of designing and a long period of in-house testing, was placed on the market for companies in need of resolving the same issues that we had in relation to broaching and slotting. The REV Broaching Tool undoubtedly represents an effective solution to these issues, as it allows broaching and slotting to be carried out directly on CNC machine tools (lathes, machining centres, milling machines, etc.), without having to set up other machines and without having to seek the assistance of subcontractors, plus, it guarantees an excellent finish and is always perfectly within tolerance. We have also discovered that the REV Broaching Tool can be successfully used on traditional machines such as slotting and shaping machines, therefore offering versatility and rigidity.

All of our customers that have used our REV Broaching Tool system thus far have expressed great satisfaction with the machining quality and the considerable savings in time and money. Customer satisfaction is our greatest achievement and the best motivation to keep improving.

The REV Broaching Tool can be used for processes requiring straight cuts, such as broaching tab or key housings, PTOs and internal gears, directly on CNC lathes, machining centres or milling machines, considerably faster and with remarkable precision. In addition to offering the significant advantage of not having to pick up the workpiece for broaching or slotting and set it up on another dedicated machine, the tool also makes sure the broaching process is carried out correctly, at the same time as the other processes. Used on slotting or shaping machines, the REV tool represents an excellent substitute for traditional tools, as it offers greater versatility thanks to the re-usable tool body and the replaceable insert. The high rigidity of the REV Broaching Tool ensures that the sharp edge of the insert has an exceptionally long service life and that broaching or slotting is carried out perfectly in line with the axis of the workpiece. The surface finish standard achieved through processing with this tool is very high. All of these characteristics together make the REV system among the most efficient and convenient mechanical precision processing systems currently available on the market. The REV Broaching Tool is available in various sizes, covering the entire range of the most common processing sizes, and each insert size can have various tolerance classes. Special insert measurements or tool shapes can be produced very rapidly, on customer demand.

The REV Broaching Tool is made with quenched and tempered tool steel. The section that houses the insert is hardened to 58/60 HRC, making it very resistant to compression and guaranteeing the tool a long service life. The REV Broaching Tool features 3.5 mm holes for the forced supply of coolant liquid which, in addition to lubricating and cooling the insert, are used to extract the chips, produced through broaching or slotting, out of the blind hole. The tool is available in two socket diameters (25 and 32). Two tool lines are available for each socket diameter: standard and long (identified by the suffix "L" in the code). We also produce special tools, based on customer demand, with great flexibility. The REV Broaching Tool differs from similar tools currently on the market by its patented eccentric bushing that completely eliminates symmetry errors. This bushing was provided so that any lathe without a Y-axis can perform processing in perfect alignment with the workpiece. The REV Broaching Tool guarantees low impact on the machine tool bearings. To date, none of the thousands of REV system users has reported issues of breakage or unusual wear caused by broaching on the CNC. Based on tests carried out by REV, the cutting force for executing key housings with a 20 mm width, for example, is comparable to the cutting force required for a common hole with a 14 mm diameter.

The processes that can be carried out with the REV Broaching Tool are, in terms of standard machining, all of those relative to broaching tab or key housings (with single or multiple timing, on cylindrical or conical holes, with or without a relief grooves, with or without 0.2mm x 45° chamfering on the base). With special tools it is also possible to execute PTOs, square, pentagonal and hexagonal holes and involute teeth, for example. 1 mm is the minimum hole size for broaching. The maximum processing depth is 200 mm, with standard machining. When it is necessary to execute considerably large key housings, it is good practice to perform the operation in two steps: a roughing phase to remove approximately 50% of the material, and a finishing phase to achieve the required size. Accordingly, you avoid excessive stress to the tool, and you improve precision and surface finish at the same time.

The materials that can be processed are:

• High and low-alloy low-carbon steel, and non-alloy steel;

• Stainless steel, quenched and tempered steel, cast iron, AVP;

• Non-ferrous materials such as aluminium alloys and titanium;

• Copper alloys, bronze, and engineering plastics.

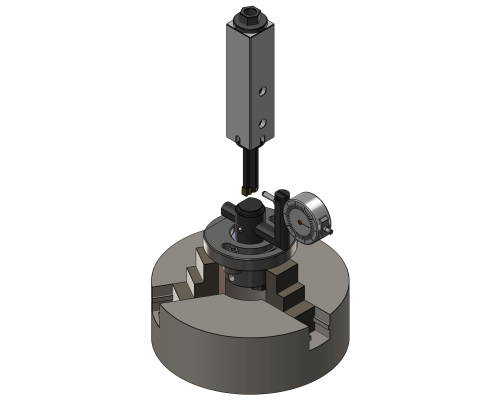

The broaching and slotting inserts are made with a sintered alloy which, following heat treatment, reaches a hardness of 72 HRC. This material gives the REV broaching inserts high toughness, and can accordingly withstand strong pressures, with the subsequent possibility of using increments of up to 0.2 mm on steel and 0.3 mm on cast iron without breakage during processing. These increments would not be possible if the inserts were manufactured with a different material, like the majority currently available on the market. The inserts are also subject to a surface treatment, TiN coating, with anti wear and seize properties. The inserts are re-sharpened by tapering their sides. This process eliminates any gouges that would prevent the insert from cutting perpendicular to the reference axis of the workpiece during the broaching phase. The protruding shape of the inserts makes it possible to re-sharpen them numerous times. All of these characteristics make REV inserts extraordinarily long-lasting. The inserts are available for immediate delivery in 27 sizes (considering millimetre and inch-based measurements), and 4 tolerance classes for each size (C11, D10, H7 and P6). Inserts measured in millilitres are identified by their code ending with "SM" and execute 0.2x45° chamfering on the intersection point between the hole and the walls of the broached slot, leaving the hole burr-free. This type of chamfering can only be carried out on UNI keys. We also manufacture special inserts on customer demand. Using re-sharpening machines for REV inserts, re-sharpening can be carried out with a standard grinding wheel. The re-sharpening machine has a comfortable grip and ensures that the insert protrudes from the rod, making the operation easier to perform.