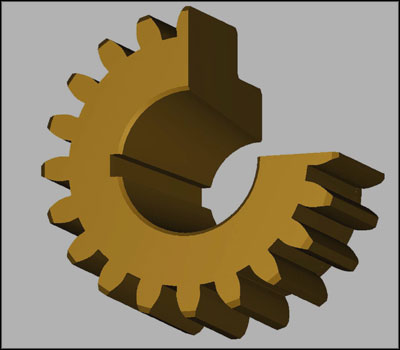

The figure above illustrates an example of broaching carried out with the REV BROACHING TOOL inside a gear with conical hole. The keyway broaching follows the profile of the conical hole and, accordingly ends up angular to the horizontal axis of the workpiece. This is a very difficult process to execute with traditional broaching and slotting machines. It is, however, very simple and quick to execute with the REV BROACHING TOOL on CNC lathes or machining centres. A completely burr-free workpiece is achieved by creating a 0.2 x 45° chamfered edge on the keyway inside the conical hole. Our company can provide specific programmes for any CNC machine currently on the market.

PROGRAMMING EXAMPLES:

Highlighted in red only the values that require editing

O1000(RECALL MACRO O1000)

#1=0 (0=INT PROCESSING 1=EXT PROCESSING)

#2=0707 (TOOL NUMBER - WARNING: DO NOT ENTER T BEFORE 0707)

#3=15.0 (Z AXIS WORK START DISTANCE)

#4=0.2 (X AXIS WORK START DISTANCE)

#5=25 (HOLE OR SHAFT DIAMETER)

#6=8 (INSERT WIDTH)

#7=3.3 (PROCESSING DEPTH ON X AXIS RADIUS)

#8=30 (PROCESSING LENGTH ON Z AXIS)

#9=6000 (CUTTING SPEED IN MILLIMETRES PER MINUTE)

#10=0,05 (INCREMENT OF EACH PASS)

#11=0 (ADMITTED DRAUGHT ERROR ON LONGITUDINAL RADIUS OF 0.25 MAX)

#12=90 (DEPARTURE ANGLE 90°/45°)

#13=2 (NUMBER OF FINISHINGS WITHOUT REMOVAL)

#14=1 (NUMBER OF OPERATIONS)

#15=0 (C-AXIS ANGLE BEFORE PROCESSING)

#16=0 (ANGLE BETWEEN OPERATIONS)

#17=1 (CODE G RETURN 0= FAST- 1=WORK)

#18=6000 (FEED BACK Z AXIS ACTIVATED ONLY IF #17=1)

#19=5 (WORKING ANGLE 0=CYLINDRICAL/WITH VALUE=CONICAL)

#20=5 (HELIX ANGLE +- INTERPOLATED WITH C AXIS)

#21=0 ( PRIMITIVE DIAMETER OF SPIRAL TEETH)

#22=35 (CODE M ON C AXIS)

#23=34 CODE M OFF C AXIS)

#24=90 CODE M BRAKE RELEASE C AXIS)

#25=89 CODE M BRAKE LOCK C AXIS)

#26=8 (REFRIGERANT 8=ON 0=OFF)

#27=1 (BRAKE 0=NO 1=YES)

M98P8000 (RECALL MACRO)

(M99=BACK TO MAIN PROGRAMME)

OR (M30=END PROGRAMME)