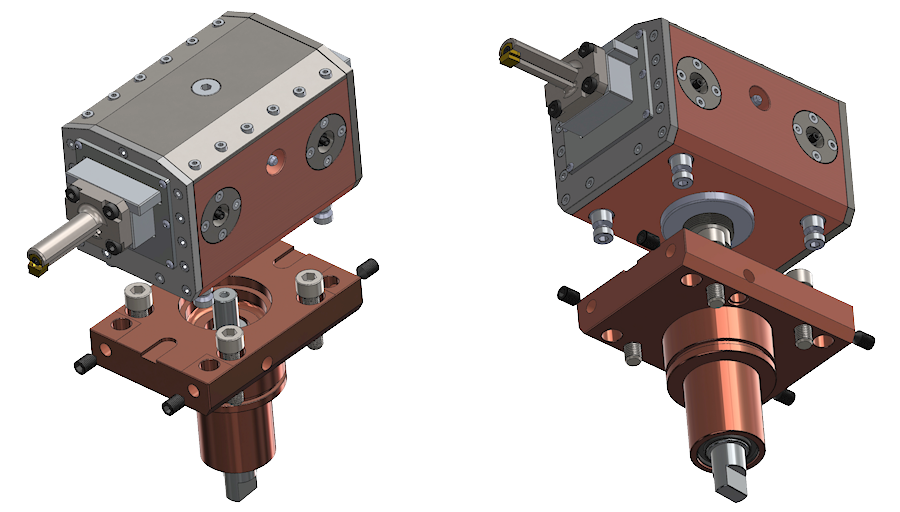

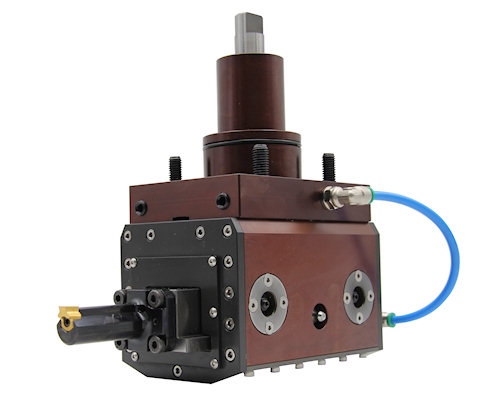

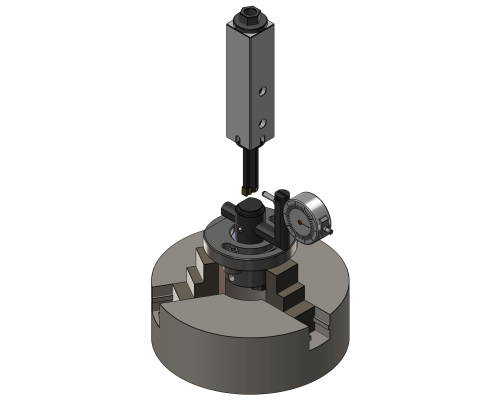

The REV Broaching Tool system is an intelligent and efficient solution to carry out key housings and slotting directly on CNC lathes and machining centres, without having to set tools up on other machines and without having to hire external specialists. All of this while guaranteeing machining with an excellent finish, and always perfectly within tolerance. The REV Broaching Tool, also used on slotting and shaping machines, is a valid alternative to traditional tools, offering greater versatility and sturdiness. The REV system is the only one that provides customers with complete programmes for use on CNCs and that provides customers with technical assistance for their every demand, without any additional cost.